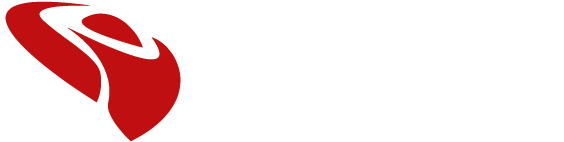

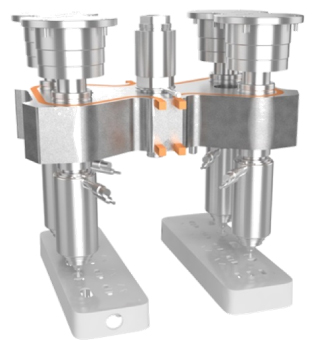

SERIE PRM

Like the PRS series, this series offers reduced cost competitiveness applicable to hot runner systems

FEATURES

- Open nozzles and valve gate for hot runner systems

- Direct injection or channel

- Pneumatic / hydraulic drive for valved systems

- Accionamiento neumático/hidráulico para sistemas valvulados

- Recommended to process commodities and engineering materials

SOLUTIONS

- Compatible tips

- Optimum value for money

- Flexibility of configurations and lengths

- Compatibility with hot half systems (MODU SYSTEM)

SERIE PRM

Like the PRS series, this series offers reduced cost competitiveness applicable to hot runner systems

FEATURES

- Open nozzles and valve gate for hot runner systems

- Direct injection or channel

- Pneumatic / hydraulic drive for valved systems

- Accionamiento neumático/hidráulico para sistemas valvulados

- Recommended to process commodities and engineering materials

SOLUTIONS

- Compatible tips

- Optimum value for money

- Flexibility of configurations and lengths

- Compatibility with hot half systems (MODU SYSTEM)

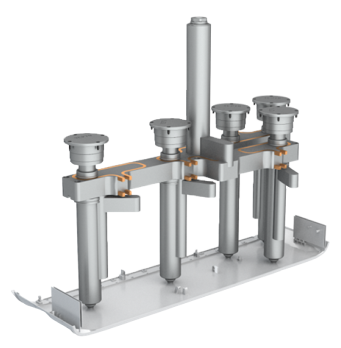

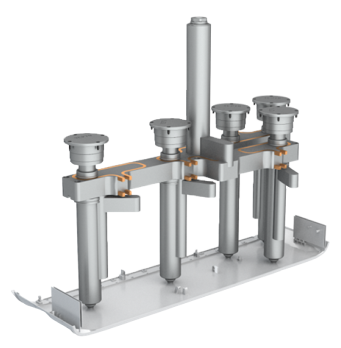

SERIE PRM-T

Threaded version of the PRM series created to improve its application by reducing mold space and machining time.

FEATURES

- Open nozzles and valve gate for hot runner systems

- Direct injection or channel

- Capacity up to 1200g (depending on project)

- Pneumatic / hydraulic drive for valved systems

- Recommended to process commodities and engineering materials

SOLUTIONS

- Compatible tips

- Easy installation

- Threaded version (also available for the S-RHEO and S-DURA series (S-RHEO-T / S-DURA-T)

- Compatibility with hot half systems (MODU SYSTEM) and pre-assembled systems (EMS)

SERIE PRM-T

Threaded version of the PRM series created to improve its application by reducing mold space and machining time.

FEATURES

- Open nozzles and valve gate for hot runner systems

- Direct injection or channel

- Capacity up to 1200g (depending on project)

- Pneumatic / hydraulic drive for valved systems

- Recommended to process commodities and engineering materials

SOLUTIONS

- Compatible tips

- Easy installation

- Threaded version (also available for the S-RHEO and S-DURA series (S-RHEO-T / S-DURA-T)

- Compatibility with hot half systems (MODU SYSTEM) and pre-assembled systems (EMS)

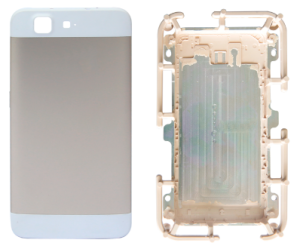

SERIE S-DURA

Option created to improve the transformation of engineering materials due to its excellent thermal stability and high wear resistance

FEATURES

- Open and valved nozzles for hot runner systems

- Direct injection or channel

- Pneumatic / hydraulic drive for valve gate systems (sequential option available)

- Recommended for processing engineering materials and reinforced materials (glass fiber)

SOLUTIONS

- Excellent thermal stability

- High wear resistance

- Compatibility with hot half systems (MODU SYSTEM) and available in S-DURA-T version for threaded systems

SERIE S-DURA

Option created to improve the transformation of engineering materials due to its excellent thermal stability and high wear resistance

FEATURES

- Open and valved nozzles for hot runner systems

- Direct injection or channel

- Pneumatic / hydraulic drive for valve gate systems (sequential option available)

- Recommended for processing engineering materials and reinforced materials (glass fiber)

SOLUTIONS

- Excellent thermal stability

- High wear resistance

- Compatibility with hot half systems (MODU SYSTEM) and available in S-DURA-T version for threaded systems

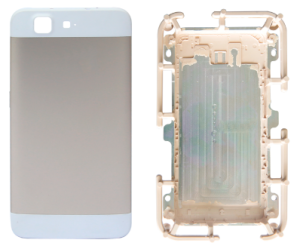

SERIE S-RHEO

Optimized nozzles for the packaging industry offering the best possible performance in parts that require frequent color changes

FEATURES

- Open and valved nozzles for hot runner systems

- Direct injection or channel

- Pneumatic / hydraulic drive for valve gate systems (sequential option available)

- Recommended to process commodities materials

SOLUTIONS

- Excellent thermal stability

- Optimal color change process

- Small parts and multi cavity systems

- Compatibility with hot half systems (MODU SYSTEM) and available in S-RHEO-T version for threaded

systems

SERIE S-RHEO

Optimized nozzles for the packaging industry offering the best possible performance in parts that require frequent color changes

FEATURES

- Open and valved nozzles for hot runner systems

- Direct injection or channel

- Pneumatic / hydraulic drive for valve gate systems (sequential option available)

- Recommended to process commodities materials

SOLUTIONS

- Excellent thermal stability

- Optimal color change process

- Small parts and multi cavity systems

- Compatibility with hot half systems (MODU SYSTEM) and available in S-RHEO-T version for threaded

systems

Runnertech Hot runner system

Polígono industrial L’Alfaç II

Calle Huelva, 19

03440 Ibi (Alicante), España

Tel: +34 965 553 199 (ext.3) | Fax: +34 966 555 168

info@runner-tech.com

Runnertech Hot runner system

Polígono industrial L’Alfaç II

Calle Huelva, 19

03440 Ibi (Alicante), España

Tel: +34 965 553 199 (ext.3) | Fax: +34 966 555 168

info@runner-tech.com